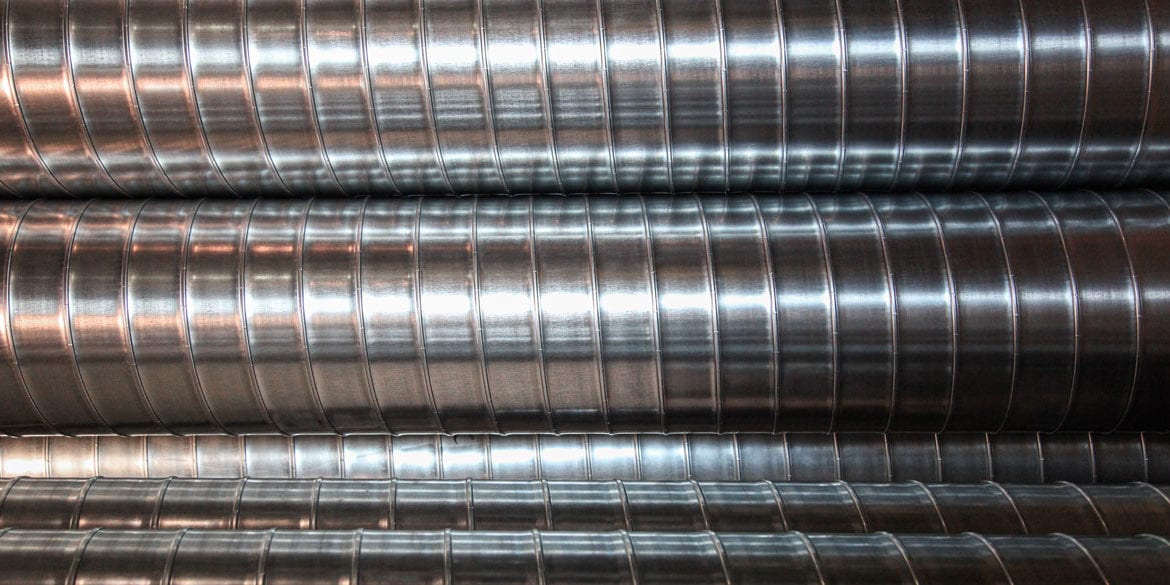

If you own or manage a building (or just have an interest in architecture), you have likely noticed the proliferation of spiral sheet metal ductwork in bars, restaurants, offices, and other commercial spaces.

Like traditional ductwork, spiral ductwork is the vital component of a commercial HVAC system responsible for circulating heated or cooled air from the central HVAC unit throughout a building. However, spiral ductwork has its own benefits that make it an aesthetic and functional option for building owners who want to save money on energy bills, maintain comfort, and improve indoor air quality in their facilities.

Keep reading to learn five benefits of using spiral ductwork in commercial HVAC systems and why commercial building owners should consider it for upcoming new construction or renovation projects.

Benefits of Spiral Ductwork

1. Less Air Leakage

Air leakage is one of the primary causes of energy loss, impaired efficiency, and poor indoor air quality in commercial HVAC systems. When engineered and installed correctly, spiral ductwork has leakage rates of less than 1% because they have fewer duct-to-duct connections (or joints) than rectangular ductwork, which is often where leakage occurs. Spiral ductwork is also formed with a lock-seam seal during the sheet metal fabrication process, which helps it meet – or even exceed – industry air leakage standards.

2. Better Air Movement

Remember how quickly and easily you glided down metal slides as a kid? Now imagine if the slide had a 90-degree angle. Air moves with similar momentum through ductwork, with velocity pressure, static pressure, and friction all coming into play. Rectangular ductwork has many sharp angles and joints that slow down airflow, but the round shape of spiral ductwork equalizes internal pressure, allowing for more efficient airflow through a building.

3. Less Expensive

Due to its inherent efficiency, spiral ductwork reduces the overall cost of heating, cooling, filtering, and distributing air in your building. It is also faster to install because it is light-weight and requires less material to hang and anchor the equipment. Additionally, spiral ductwork can be less expensive to transport if smaller pieces are nested within larger ductwork.

4. Less Noise

Reverberation is one of the primary sources of noise in traditional ductwork. However, the gentle curvature of spiral ductwork causes less turbulence than rectangular ductwork with sharp corners. This creates a quieter atmosphere in offices, schools, hospitals, and other commercial buildings.

5. Easier to Maintain

Spiral ducts are easy to clean and maintain because they do not have large flat surfaces and corners inside to collect dust and other contaminants. Cleaning tools that professional HVAC service technicians use for spiral systems today are efficient and economical, allowing building owners to ensure their HVAC systems run efficiently for years to come if the equipment is inspected at least once a year.

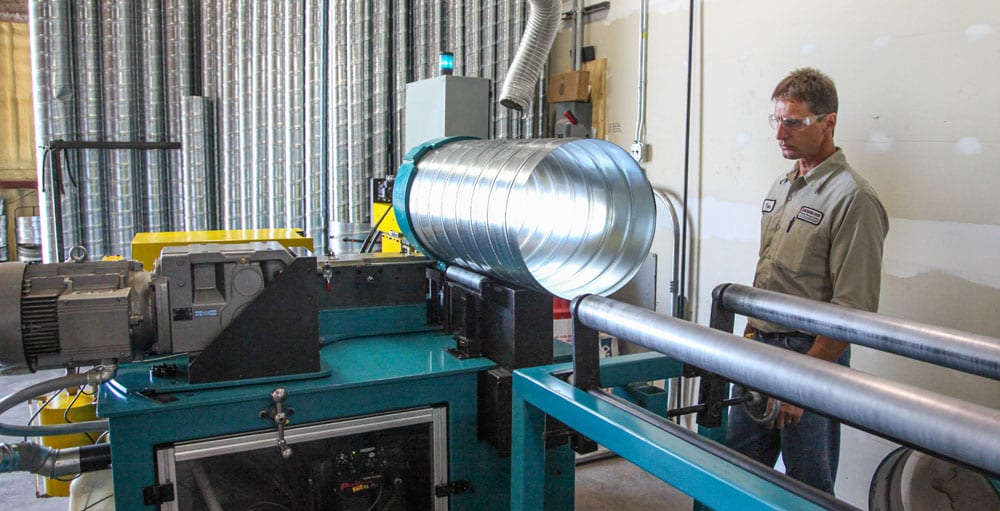

Custom Aire proudly creates custom spiral ductwork right in our state-of-the-art sheet metal fabrication shop that fits seamlessly and operates effectively for commercial buildings in every major industry. To learn more about the benefits of spiral ductwork, contact us today.