Air ducts may not be something people think about often, but if you own or operate a commercial building, ductwork is an integral part of your HVAC equipment. Before central HVAC systems became mainstream in the early 20th century, people needed to stay close to a heat source to survive cold winters and cooling options in the hot summer months came along decades later. Thanks to air ducts, building occupants get to feel comfortable all year long, in any room in the conditioned space of your building.

However, to operate at maximum efficiency, your ductwork needs to be properly designed, sized, and sealed. Keep reading to learn more about duct sizing and the role it plays in maintaining comfortable conditions, low energy bills, and healthy indoor air quality.

Ductwork Basics

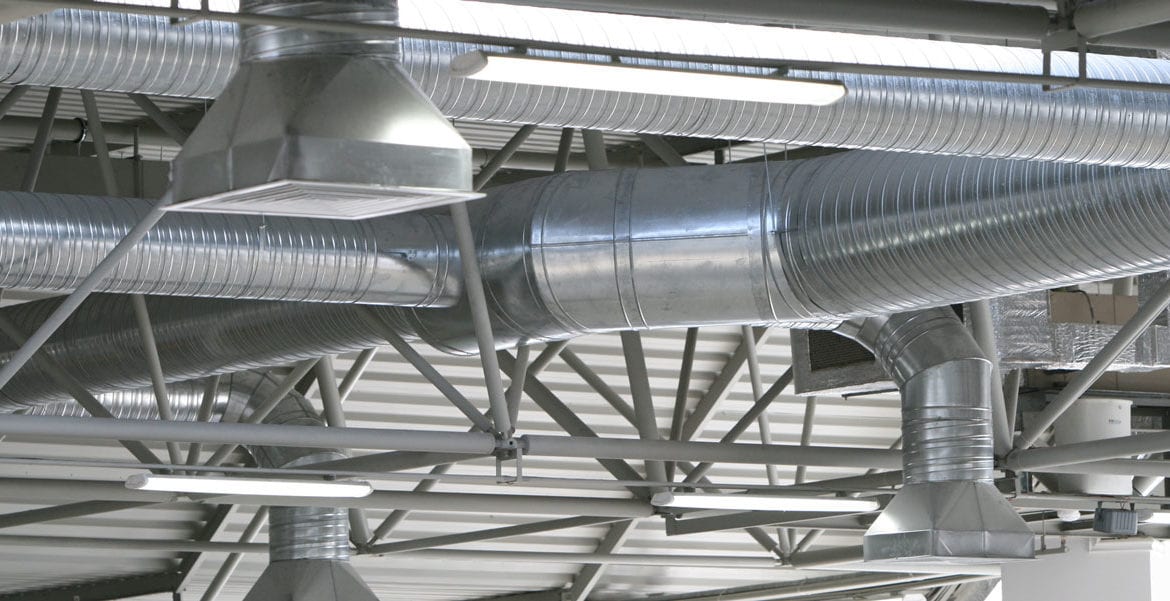

Air ducts are networks of tubes that circulate air between a centralized HVAC unit and the conditioned space of a building. Traditional ductwork is rectangular, but designs have included more energy-efficient spiral structures in recent years. Ducts are typically manufactured with galvanized steel, aluminum, or stainless steel, but they can also be created with flexible plastic, fiberglass, or fabric, depending on application.

Different Functions

An average commercial HVAC system has a variety of ducts that perform specific functions throughout the operation cycle. Some of the main types of ductwork include:

- Supply air ductwork –Carries conditioned air from the HVAC unit to rooms within the conditioned area

- Return air ductwork– Removes air from the conditioned space and brings it back to the HVAC unit to be reconditioned

- Fresh air ductwork– Supplies outdoor air to the HVAC unit to ventilate the conditioned area

- Exhaust air ductwork– Discharges air from bathrooms, kitchens, labs, and other areas requiring ventilation to the outdoors

- Mixed air ductwork– Supplies a mixture of outdoor air and return air to the HVAC unit to be conditioned

Necessary ductwork for any commercial HVAC system depends on building size, space availability in each room, and the type of activity happening inside the building, among many other considerations.

Why Size Matters

Duct size is determined by the amount of air that must pass through it including every twist and turn to efficiently maintain balanced temperature, air pressure, and humidity levels within a structure. Inadequate duct size makes your HVAC system work harder to achieve these factors, leading to higher energy bills and increased risk of equipment breakdown. Leaky ductwork only aggravates these issues further and decreases your indoor air quality by introducing airborne pollutants into your air supply.

To find the perfect size, HVAC professionals use a formula that considers the size of your unit, required air flow velocity, friction loss, static pressure, and square footage of every room that needs to be conditioned.

For utmost efficiency, ductwork design should be considered in the early stages of building development or renovation. It’s also important to have a certified technician check your HVAC system at least once a year to change air filters, clean the ductwork, and catch any leaks or other inefficiencies.

Whether you’re starting a new project or maintaining an existing building, Custom Aire is here to ensure your buildings HVAC system is running in tip-top shape. In addition to commercial HVAC system installation and maintenance services, we also provide custom sheet metal fabrication in our shop to create ductwork that fits just right for any commercial project. Contact us today to learn more.